In the fast-paced world of electronics design, both researchers and manufacturers are under pressure to deliver reliable products with shorter lead times and ever-evolving designs. Rapid validation of printed circuit boards (PCBs) is crucial, and one of the most critical yet underappreciated tools enabling this speed and flexibility is the precision IC socket. These sockets lie at the heart of reconfigurable test platforms, allowing for fast iterations, minimal downtime, and reliable, solder-free testing.

Why Reconfigurable Test Platforms Are Vital

Modern PCBs—used in automotive electronics, consumer devices, and advanced communication systems—demand thorough and iterative testing. Delays or failures at the validation stage can be costly. Reconfigurable test platforms:

Allow modular testing without redesigning test fixtures.

Support rapid IC swapping without rework or soldering.

Enable multi-variant and supplier testing with ease.

Shorten iteration cycles, increasing innovation speed.

The Role of Precision IC Sockets

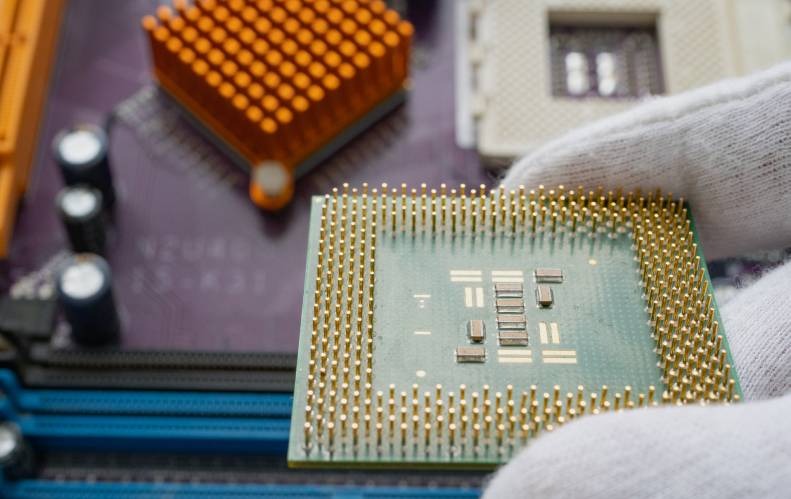

Precision IC sockets act as electromechanical interfaces, enabling repeated insertion and removal of chips during testing. Unlike direct soldering, they provide temporary yet reliable connections without damaging the board or component. They are essential for:

Eliminating soldering-desoldering cycles during iterative prototyping.

Supporting thousands of insertion/removal cycles (50K–100K in high-cycle models).

Preserving PCB integrity and expensive ICs during repetitive tests.

Core Design Features of High-Quality IC Sockets

Durability: Spring-pin and gold-plated contacts ensure longevity and contact reliability over thousands of cycles.

Thermal Stability: Burn-in capable designs endure temperature extremes during stress testing.

Low Signal Distortion: Kelvin or coaxial pin architectures maintain signal integrity at high frequencies.

Form Factor Compatibility: From DIP and QFP to fine-pitch LGA and BGA sockets, options support evolving IC packaging trends.

Solderless Attachment: Compression-mount or press-fit designs reduce rework time and risk.

Key Benefits for PCB Validation

Flexibility and Versatility

Rapid chip swapping supports variant testing and experimentation.

Ideal for R&D and prototyping where configurations change frequently.

Testing and Debugging Efficiency

Enables in-circuit, burn-in, and system-level tests without PCB damage.

Facilitates fault isolation, firmware flashing, and parametric assessments.

Cost Savings

Reduces IC/PCB damage from soldering errors.

Saves time by avoiding board remanufacturing in each iteration.

Prolongs equipment life by minimizing soldering wear.

Scalability for Production and QA

Supports automated test handlers.

Standardizes test procedures across product lines.

Simplifies board rework and chip replacement during QA or failure analysis.

Case Study Snapshot

A mid-sized electronics company implemented ZIF and DIP sockets for validating controller ICs across evolving board designs. By avoiding PCB re-spins and enabling multi-variant testing, they cut lead time by over two weeks per revision—resulting in significant cost and time savings.

| Application Area | Role of Precision IC Socket | Benefit |

| Prototyping | Enables repeated IC swapping and variant trials | Accelerates iteration, reduces prototyping costs and risks |

| Production Testing | Interface for automated test handlers | High-speed, reliable throughput for QA |

| Failure Analysis | Enables easy extraction for root cause diagnostics | Reduces debugging time, preserves board/investment |

| Firmware Development | Temporary interface for in-system programming | Quick code update cycles, less solder/desolder wear |

| Research & Experiment | Flexible testbed for various devices | Deepens studies, lowers material waste |

| Field Service/Repair | Fast, solderless chip replacement in situ | Minimizes downtime and service costs |

Types of Precision IC Sockets

Zero-Insertion-Force (ZIF): Ideal for high-pin-count or fragile ICs.

Burn-in Sockets: Withstand prolonged thermal cycling during reliability testing.

Fine-Pitch Sockets: For ultra-dense ICs (as tight as 0.25mm pitch).

Kelvin/Coaxial Sockets: Preserve signal fidelity in high-speed or analog testing.

Spring-Pin and Elastomer: Low contact resistance, ideal for RF and high-speed digital.

Compression/Press-Fit: Enable rapid prototyping and quick replacements.

Best Practices for Teams

Practical Guidelines for Companies and Researchers

For Companies (OEMs, ODMs, Manufacturers):

Invest in quality sockets for critical validation stages—cheap sockets can cause intermittent connections and false test negatives[4][1][2].

Design for Testability (DFT): Incorporate socket footprints into engineering prototypes and early production boards to facilitate exhaustive validation and rework[5][6].

Plan for scalability: Modularize test fixtures to support new IC variants with minimal downtime.

Document socket specifications and test protocols to ensure consistent QA results across batches and facilities[5][2].

Combine socket-based testing with automated handlers for rapid throughput in mass production environments[4][2].

For Researchers and Developers:

Use sockets early in the design cycle for maximum flexibility—reconfigure your board as research evolves.

Select sockets compatible with your IC packaging—pay attention to pin pitch, current, and frequency specs[4][1][2].

Prioritize low-insertion-force designs for fragile or expensive prototype chips.

Document each configuration and test outcome—socket re-use enables accurate A/B comparisons.

Leverage sockets during firmware and parametric tests; they simplify in-system or in-circuit programming cycles[7].

Challenges & Solutions

| Challenge | Solution |

| Signal integrity degradation at high speeds | Use Kelvin/coaxial sockets and perform signal deembedding |

| Wear and tear over time | Track usage cycles and replace sockets based on performance metrics |

| Mechanical misalignment | Maintain tight tolerance on PCB/socket footprints |

Looking Ahead: The Future of Socket-Based Validation

With ICs becoming smaller and more powerful, test environments must support finer pitches, higher frequencies, and harsher conditions. Next-gen sockets now handle up to 75 GHz bandwidth and temperatures from -55°C to 160°C. As PCB validation becomes more reliant on design-for-test methodologies, socketed platforms will continue to play a central role in enabling fast, reliable, and cost-effective product development.[8][2].

Continued integration between design-for-test methodologies and reconfigurable platforms—supported by these advanced sockets—will help companies and researchers cut time-to-market, boost reliability, and support ongoing innovation.

Conclusion Precision IC sockets aren’t just accessories—they are essential enablers of reconfigurable, modular, and future-proof PCB test platforms. Whether you’re refining an experimental prototype or validating a production board at scale, integrating precision sockets reduces risk, accelerates development, and enhances test coverage. As demand for speed and accuracy continues to grow, the strategic use of IC sockets will remain a competitive differentiator in electronics design.

https://www.mill-max.com/engineering-notebooks/ic-sockets

https://www.pcbaaa.com/ic-socket

https://cdn2.hubspot.net/hubfs/353296/ebook_pdfs/Design_guidelines_for_in-circuit_testability.pdf

https://www.protoexpress.com/blog/design-for-testing-guidelines-pcb-manufacturing

https://www.nextpcb.com/blog/a-comprehensive-guide-to-ic-programming-in-pcb-assembly https://www.semiconductors.org/wp-content/uploads/2018/09/Test.pdf